intro

problem

Electric angle grinders are not common in today's industrial setting, mainly due to the fact that they do not last for more than a couple of months or even weeks before they break. This is partly due to cheaper materials and manufacturing methods, but also the sensitivity of the electrical components compared to pneumatic grinders. To fix this was one of Atlas Copco's main goal in proposing this project, and as designers and not engineers me and David isolated 2 areas of durability where we could have the biggest impact: repairability and aesthetic expression.

aesthetics

This part of the project was done by David, exploring the outward appearance of the angle grinder, and how to make it look timeless. An important factor to this was to show and consider the product as it appears most commonly, worn and heavily used.

Render by David Dahlberg

repairability

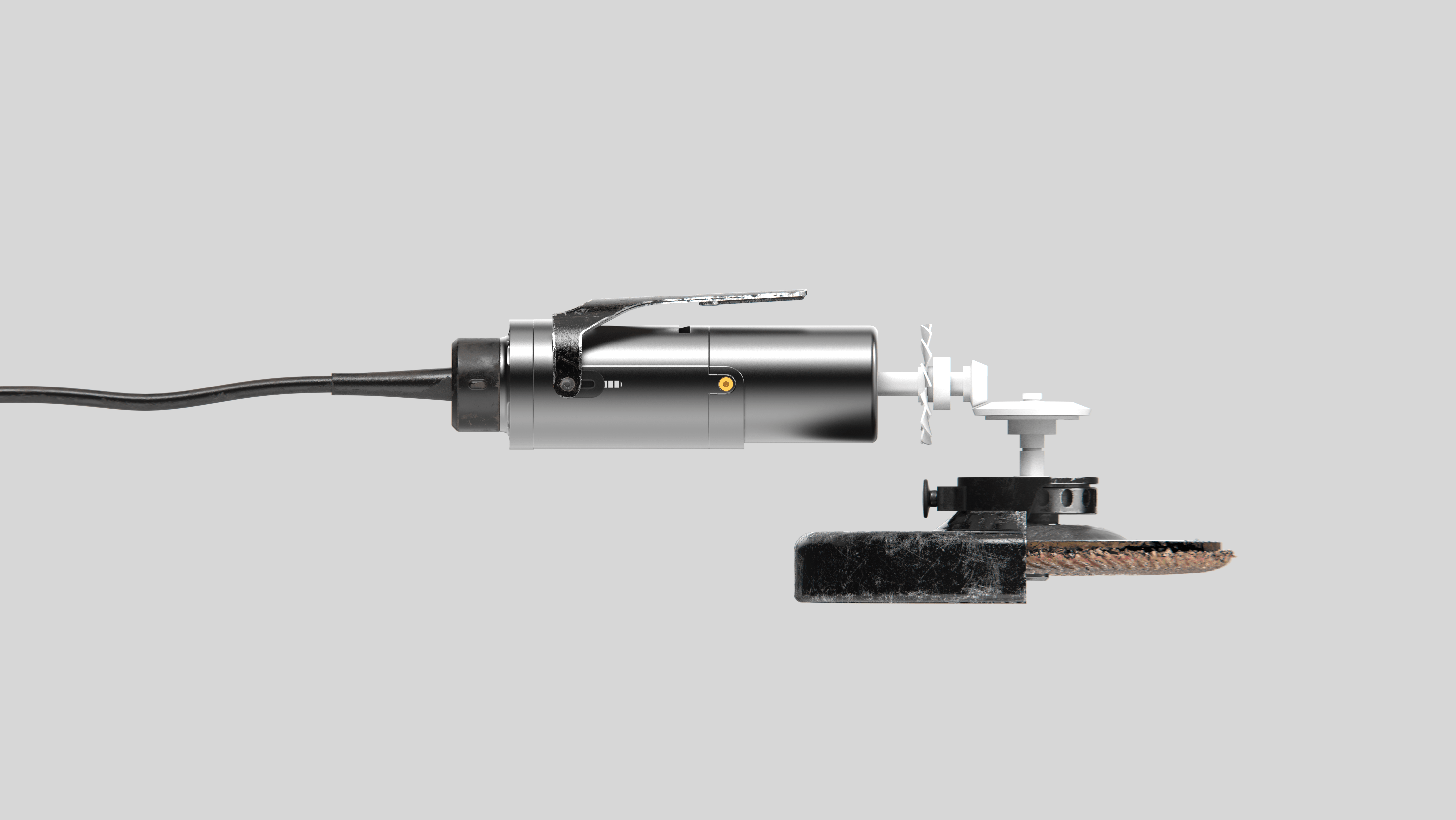

After dismantling the product and visiting workshops where they were used, two key problems were discovered regarding durability. The angle grinders break frequently, and when they do they are not being repaired.

To explore how to make the users repair their tools, I focused on the experience of repairing the product, and how the aesthetics could both invite and guide you through the repair process.

Of the failures from the workshops, the most common was cord breakage, followed by motor failure and then overheating, usually caused by dust or overuse. I therefore designed the internals to effectively cool the engine, protect from dust, and give quick access to exchanging key parts like the motor. Instead of the whole product being sent back to Atlas Copco for repair, a factory worker could send only the faulty part and get the tool running instantly.